Compressed Air Quality Testing Instruments

How clean is your compressed air and gas? Does it meet industry standards?

Compressed air is important in many industries. However, contamination of your compressed air and gas system can lead to poor product quality, damage to machines and high costs in food, pharmaceuticals and automotive production areas.

Therefore, compressed air quality testing should be done on a regular basis to detect oil, water and particles that may cause the problems.

SUTO iTEC provides high-level compressed air quality monitoring solutions for more than 20 years. Our real-time compressed air testing solutions enable companies around the world to maintain clean air and ensure their systems meet industry standards, like the ISO 8573-1.

Compressed Air Quality

S600 Portable Compressed Air Purity Analyzer

S220 Dew Point Sensor for Compressed Air

S601 Stationary Compressed Air Purity Monitor

S605 Portable Breathing Air Quality Analyzer

S606 Stationary Breathing Air Quality Monitor

Compressed air quality measurement and ISO 8573-1

How does precise compressed air monitoring prevent expensive production downtime?

Having poor compressed air purity can lead to product contamination, damage to machinery and consequently to production failures. A reliable compressed air and gas purity testing process helps to avoid such risks and guarantees that compressed air purity is within the limits set by ISO 8573-1.

This standard classifies compressed air purity based on three key factors:

- Oil content (measured in weight per volume [mg/m3])

- Particle concentration (measured in counts per cubic meter [cn/m3])

- Water concentration (measured as dew point temperature [°C Td])

Below, we answer key questions about compressed air quality testing and explain why SUTO iTEC’s solutions are essential.

Operators should ask these questions when considering compressed air purity testing:

- Is the compressed air free from oil, water, and particles?

- Is the dew point at a safe level?

- What ISO 8573-1 class does the compressed air have?

- Do filters and dryers work properly?

- Is the air regularly checked and calibrated?

- Are there contamination sources or leaks?

- Can energy costs be reduced?

- Is the air safe for employees and processes?

Regular compressed air quality testing helps detect problems early and prevents costly failures. Our experts are happy to provide guidance.

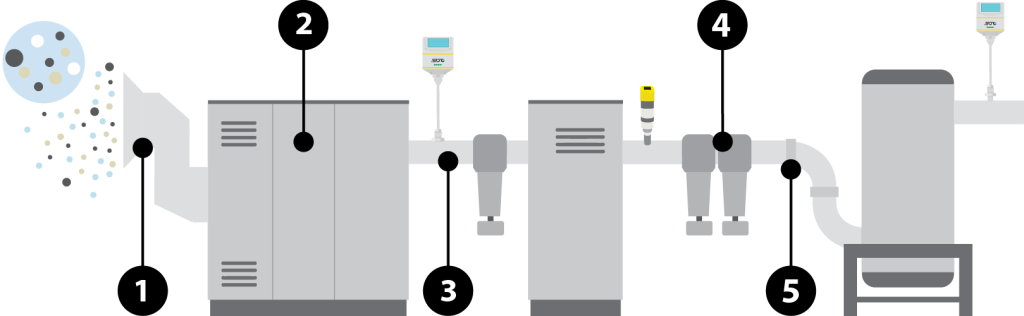

Compressed air and gas systems can be affected by many contamination sources:

- Compressor Air intake: Dust, moisture, and oil vapors from the environment

- Compressors: Wear particles and contaminants / lubricants

- Pipes and fittings: Rust, scale, and debris buildup

- Filters and dryers: Clogging or malfunctions

- Leaks: Entry of dirt and moisture

A frequent compressed air purity test at those key areas of the compressed air system helps to identify issues immediately before it is too late. It helps to keep the compressed air clean and protects production processes.

The ISO 8573-1 standard defines air quality classes to ensure clean and safe compressed air purity worldwide. It focuses on three key parameters:

- Particles: Solid contaminants in the air (measured in µm)

- Water content: Determined by the pressure dew point (°C)

- Oil content: Oil concentration in the compressed air (mg/m³) (Often produced by the compressor)

SUTO iTEC provides complete testing kits to help companies measure their compressed air and gas quality. These instruments ensure systems follow the required purity levels based on ISO 8573-1.

Traditional compressed air testing has always been sampling and external analysis. It was slow, expensive, and provided only a single snapshot. Changes in the compressed air quality or filter failures often went unnoticed and increased risks.

With SUTO iTEC’s S600 and other real-time monitors, compressed air quality testing becomes faster, more accurate, and more reliable. These advanced sensors continuously measure oil, particles, and moisture right at the source. Instead of waiting for lab reports, operators get instant insights, allowing them to catch problems early, prevent downtime, and maintain high safety standards.

Live compressed air quality monitoring makes costly lab tests unnecessary, while improving efficiency and system reliability.

Looking for the right solution? Contact our experts for more information here.

SUTO iTEC provides high-precision compressed air testing equipment to detect contamination early and help maintain compressed air purity.

Our Testing Solutions:

- S120 Oil Vapor Monitor: Detects oil contamination early, ideal for ISO 8573-1 audits. Can be used as portable or stationary instrument.

- S130/S132 Particle Counters: Particle measurement in compressed air with innovative pressure diffuser.

- S600 Portable Compressed Air Analyzer: All-in-one handheld device for flexible measurements at the point-of-use and compressed air quality audits.

- S601 Stationary Compressed Air Monitor: Monitors particulates, humidity (dew point) and residual oil in one unit 24/7.

- S520 Mobile Dew Point Meter: Handheld device to measure the dew point through the whole system.

- S211/S215/S220 Stationary dew point measurement: Accurate humidity monitoring with integrated pressure measurement.

The ideal placement of measurement devices depends on the application. Industries like food, beverage, pharma have different requirements for their compressed air quality.

Typical installation locations or point-of-uses include:

- After the dryer or filter: To ensure proper air treatment and verify dry, clean air.

- At critical usage points: Directly at machines or processes with high purity requirements.

- In contact with products: Wherever compressed air comes into contact with products, contamination can lead to quality defects.

Strategic placement ensures maximum efficiency and prevents costly damage from contaminated compressed air. Our experts at SUTO iTEC are happy to assist you in finding the best test solution for your application. Our local partners around the world are there to provide direct audit services.

- Oil vapor sensors (e.g., S120, S600/S601) use PID technology (photoionization detectors). UV light ionizes hydrocarbons, enabling real-time measurement of oil vapor – reliable detection of the critical parameter oil vapour, which can only be removed with activated carbon.

- Particle counters (e.g., S130/S132, S600/S601) work with laser optical measurement. A laser beam detects particles based on light scattering, determining their quantity and size according to ISO 8573-1 and ISO 8573-4.

- Real-time monitoring: Detects contamination instantly.

- Accurate sensors: Provides reliable air quality data.

- Simple operation: User-friendly software for easy integration

- Seamless integration: Compatible with existing systems

- ISO 8573-1: Measuring instruments for the determination of particle, moisture and residual oil content as defined in the standard.

With SUTO iTEC’s compressed air test equipment, businesses can maintain compressed air and gas purity, reduce downtime, and improve efficiency.